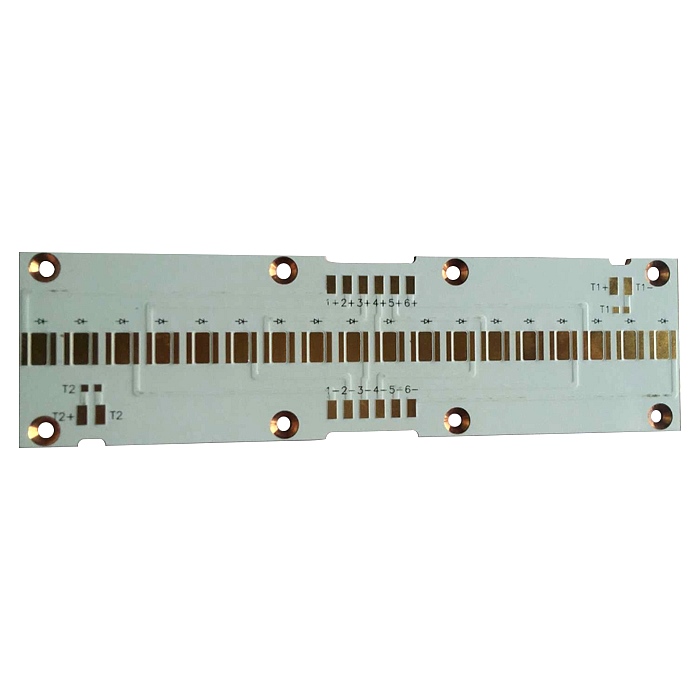

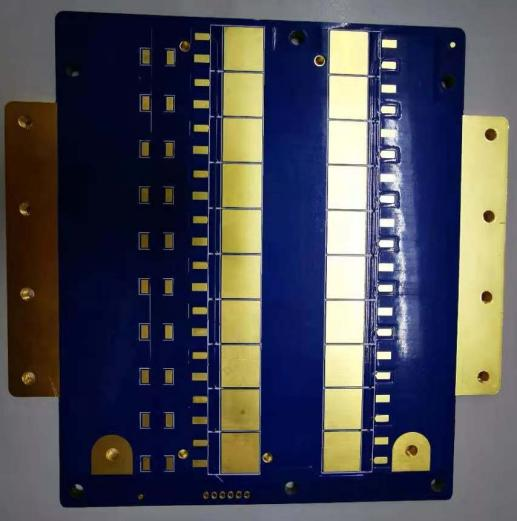

Copper substrate PCB

Product description

The superior thermal conductivity of copper substrate PCB makes it widely used in many fields such as automotive, medical, lighting, military industry, etc., and the output is increasing year by year. The copper substrate is mainly divided into: single-sided copper substrate, double-sided copper substrate, multi-layer Copper substrate, mixed press copper substrate (copper plus FR4, copper plus aluminum, copper plus ceramics), thermoelectric separation, embedded copper substrate, etc., our company provides material selection, thermal conductive adhesive configuration, process evaluation, circuit design, reliability Analysis, cost control and other aspects cooperate with customers to develop and customize.

Copper substrate PCB generally adopts T2 red copper material, conventional base material thickness: 0.2-6.0 MM, general line copper thickness: 1-10 OZ, special base material thickness and line copper thickness, can be pressed separately according to product functional requirements, surface treatment Most of them are OSP and immersion gold, and the back of the single panel can be brushed, which can resist scratches, wear resistance and look beautiful.

The thickness of thermal conductive adhesive for metal substrates is generally: 50um, 75um, 100um, 150um, and the thermal conductivity is 1-12W. It needs to be selected according to the heat conduction requirements of the product and the resistance to electrical breakdown, but the thermal conductivity and electrical breakdown resistance are contradictory. , Theoretically, the thinner the same thermal conductive adhesive is, the better the thermal conductivity is, but the resistance to electrical breakdown will be weaker, so professional technical support is needed to cooperate with customers to better select materials or develop and customize, so as to ensure the reliability of the final product performance and service life.

Send Inquiry