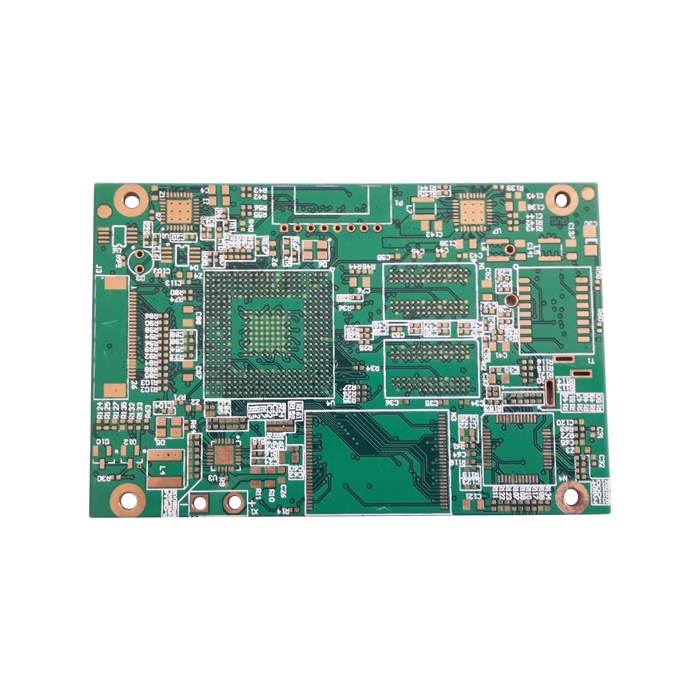

The appearance inspection standards of PCB circuit boards are designed to inspect all aspects of the products before shipment and provide customers with quality references to ensure that the quality meets the requirements. It can be roughly divided into obligatory inspection items such as appearance, solder mask, characters, wiring, PAD, and drilling.

1. When inspecting the appearance of the circuit board, the items to be inspected include the external dimensions, board thickness, V-CUT, the amount of tin eaten, the bending of the board, whether the side of the board is bumped, whether the interlayer is separated, and whether there are white spots and white spots, etc. ;

Second, the solder mask must be inspected for color difference, copper exposure, scratches (no copper exposure), whether the ink is uniform, whether the ink is on PAD, whether there is any foreign matter, whether there is a solder mask, whether it is poorly repaired, etc.;

3. The content of the character inspection includes whether the character color is correct, whether the character ink pollutes the board surface, whether it is clear, whether it is missing or ghosting, whether it is off, whether the character is on the pad, etc.;

4. Circuit inspection is more important. Compulsory inspections include whether the circuit is broken or short-circuited, whether the circuit is polluted, oxidized, scratched, and skewed, whether the circuit is warped, whether there is a gap, whether there is copper exposed, residual copper and tin, Whether the line width and line spacing are qualified, whether the line is peeled off, and whether there is crushing and depression, etc.;

5. PAD inspection includes whether PAD has gaps and exposed copper, whether there is tin shrinkage, whether optical spot detection is poor, whether BGA tin spraying is uniform, whether there is a hole on the PAD, whether the PAD is peeled off and oxidized, whether there is solder resist ink, Whether the NPTH hole is made of tin ring on the solder mask, etc.;

6. During drilling inspection, it is usually necessary to check whether the hole is overdrilled or missed, whether the hole is drilled, whether the hole is broken or plugged, whether the hole size is qualified, whether there is green paint in the hole, whether the NPTH hole is tinned, PTH hole Whether the inner tin surface is oxidized and discolored, etc.;

In addition to the above, it is also important to check whether the PCB board is mixed, whether the UL mark and production cycle are correct, and whether the manufacturer's logo is missing.