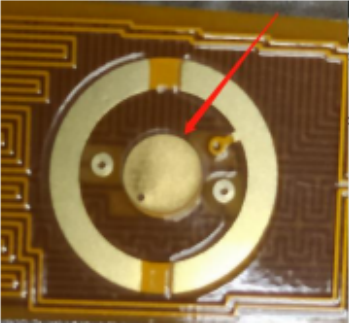

When due to negligence in design, or due to errors in production, the FPC soft board pad leaks out of the window (as shown in Figure 1), cannot be soldered, and cannot be put into use. The FPC soft board has a long process and high value. If it is scrapped and redone, it will not only be costly, but also waste time and delay delivery. It may also delay the introduction of this PCB application product into the market and cause significant losses. At this time, it can be repaired. Window pads to reduce the cost waste caused by negligence and a series of chain reactions caused thereby. Although it takes a certain amount of time and cost to repair the board, it is much faster and the cost is much lower than scrapping and redoing. It can minimize the loss in the shortest time, with low cost and high efficiency, and meet customer needs.

How to repair the FPC soft board with the open window? The material covering the pad of the soft board is polyimide material, unlike the solder mask of the hard board, it can be quickly removed with a scalpel, and it is easy to scratch the board. You need to use a laser to first put the pad on the surface After removing the cover film of the solder, expose the pads, clean the surface, and then perform gold repairing (the effect of gold repairing is shown in Figure 2 below). The repaired FPC soft board can be used normally without any problems in welding performance and function. Compared with the FPC soft board made in the normal process, there is no difference in quality.

Repairing boards is just a remedial measure for defective products caused by negligence and mistakes, and is by no means a customary operation. In production, careful work is needed to avoid batch quality problems. Although some mistakes can be made up by taking supplementary measures, they will also delay delivery and increase costs; and some mistakes cannot be made up.

Figure 1: The figure indicates the pad leakage window

Figure 2: After removing the cover film on the surface of the pad with a laser, and then repairing the gold treatmentFPCSoft Board Products