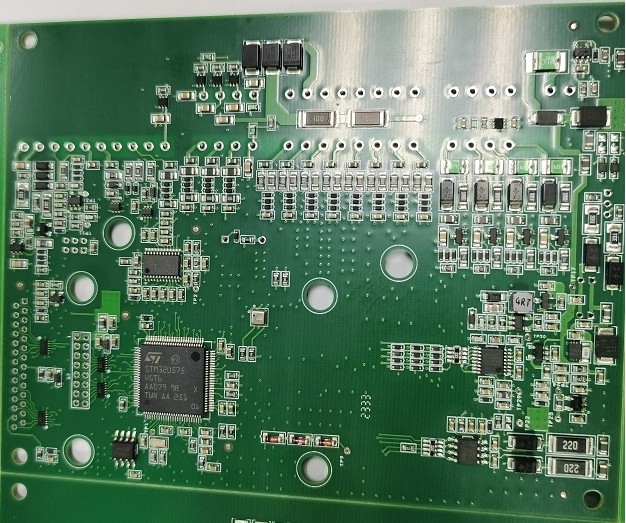

PCBA (Printed Circuit Board Assembly)Refers to a manufacturing technology that solders electronic components to printed circuit boards. InPCBAIn the program development and manufacturing process, inspection is a very important link. The following will introducepcbaThe meaning of inspection standards and the importance of strict compliance with inspection standards to product quality.

PCBAprogram development

PCBAprogram development is the entirePCBAThe first step in manufacturing. In the solution development stage, engineers will select the appropriate solution based on demand and design requirements.PCBMaterials, components, processes, etc. form a complete solution. The quality of solution development directly affects the quality and stability of the final product.

PCBAmanufacturing production

existPCBAThe manufacturing and production process involves multiple links, including component procurement, patching, welding, testing, etc. Each link needs to be strictly controlled and tested according to corresponding inspection standards to ensure the quality of the final product.

PCBAinspection standards

PCBAThe inspection standard refers to the inspection standards during the manufacturing and production process.PCBAA series of standards and specifications for product testing and verification. These standards and specifications mainly include the following aspects:

Appearance inspection: InspectionPCBAWhether the appearance is intact, whether there are scratches, deformation and other problems.

Dimensional and positional tolerances: CheckPCBAWhether the size and position of the upper components meet the design requirements.

Functional testing: VerificationPCBAWhether the functions are normal, including power supply, signal processing, communication and other functions.

Welding quality: Check the quality of the welding points, including whether the pads are fully wetted and whether the solder is uniform, etc.

Environmental suitability testing: InspectionPCBAWorking stability and reliability under different environmental conditions

The importance of strict compliance with inspection standards

strictly adhere toPCBAInspection standards are crucial to product quality. First of all, inspection standards can help companies ensure the consistency and reliability of products. Through strict testing of each link, potential problems can be discovered and corrected in time to prevent defective products from entering the market. .Secondly, complying with inspection standards can improve production efficiency and reduce costs. Through standardized inspection processes, rework and scrap caused by product quality problems can be reduced, and production efficiency and product quality can be improved.

Finally, strict compliance with inspection standards can enhance the competitiveness of an enterprise. In a highly competitive market environment, only by providing high-quality products can we win the trust and support of customers..